Services

Test

Cleanliness analysis prevents deterioration of component functionality, reducing the risk of potential damage to systems, and is an indispensable element of quality assurance.

Our inspections can be used for initial sample presentation, evaluation, re-qualification, routine tests and production control. Under the standards VDA 19.1:2015 and ISO 16232:2018 Our inspections are used in industrial sectors such as the automotive, aeronautical, electronics and plastic amongst others.

Qualification test

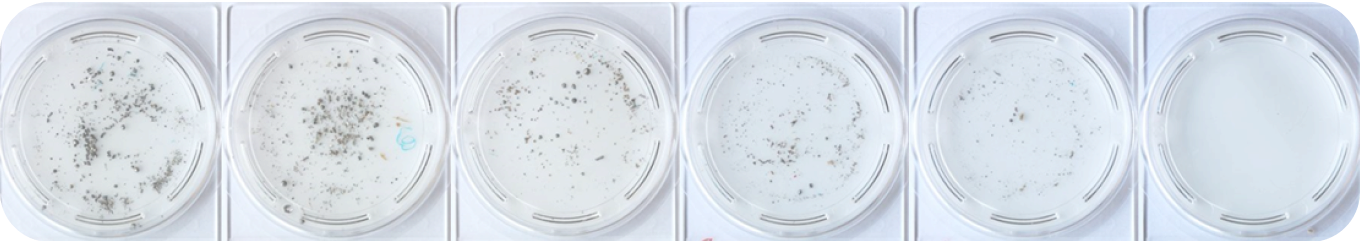

The qualification test is performed to determine the appropriate extraction conditions for a component or a group of similar components (family of components) and define an “inspection specification”. By carrying out repeated extractions of a component, it can be determined if the amount of recovered particles is decreasing and, therefore, if the extraction method applied is adequate.

Light Microscopy Testing

An optical analysis is used to validate the cleanliness specifications established in the customer-supplier relationship. It may or may not include a gravimetric analysis if specified. In this type of analysis, particle differentiation is done by brightness-no brightness.

Electron microscopy testing

SEM/EDX analysis is a combined analysis technique that counts and measures particles using a scanning electron microscope (SEM) and determines their material composition using energy dispersive X-ray spectroscopy (EDX). By assigning the particles and their size to specific material classes, complementary information about their potential for damage or possible source of origin can be obtained.

Extended analysis is applied in the field of process optimization and root cause investigation to obtain complementary information on the origin of particles.

Gravimetric analysis

This test is used to determine the total mass of particulate loading extracted from a test component by weighing the test filter with a balance before and after performing an extraction.

The result of the gravimetric analysis is called the residue weight and represents an integral value. Gravimetric analysis does not provide information on the quantity, size or nature of the particles in question and, therefore, although it may be necessary, by itself it provides little information and is often combined with additional analyzes such as For example, optical analysis.

Ask us

Call us at +34 931 595 691

Alternatively, fill out the following form, and we will contact you as soon as possible